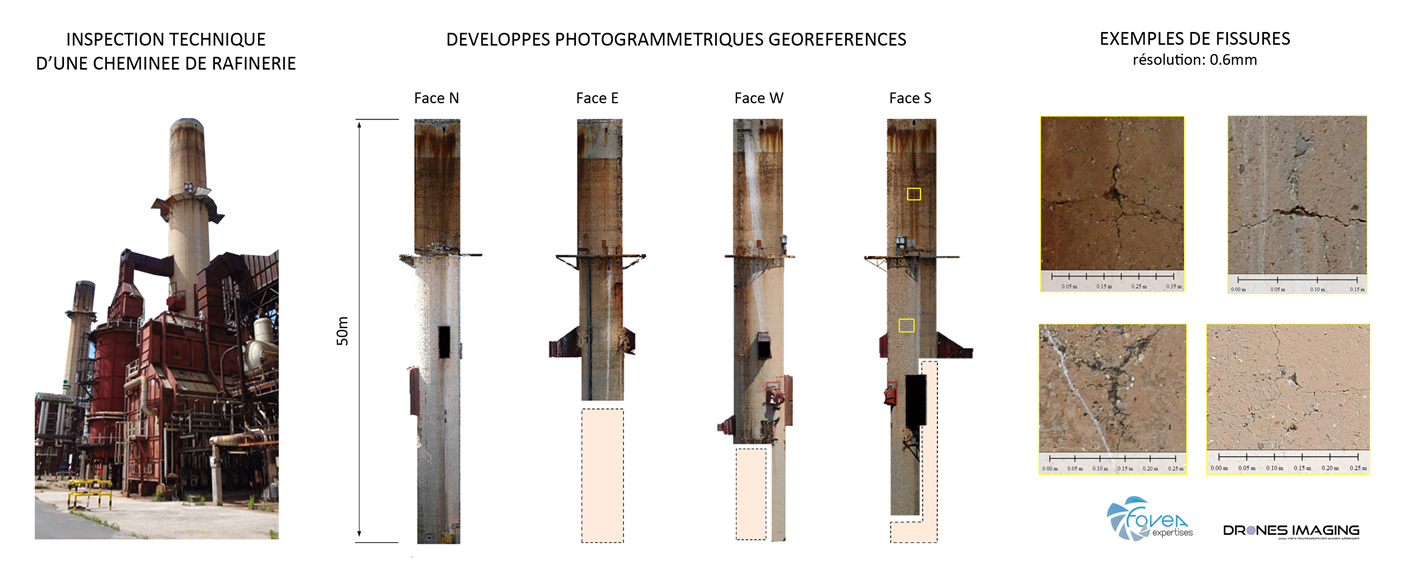

Inspection of a cracking tower and detection of disorders

Inspection of a cracking tower: Photogrammetry views of the 4 sides of the chimney. Job done from 6500 aerial shots taken by the company Fovea Expertises, specialized in technical inspections by drones.

Orthophotos of the each face

The flight automation programmed with the drone X6 Mikrokopter allowed to photograph the whole 360° cracking tower (with ultra high definition: pixel at 0.6 mm). The images acquired were then used to model the structure in 3 dimensions, allowing the export of 4 georeferenced orthofaces. These 4 orthophotos were sent directly on D+3 to the design office responsible for quantifying and locating the defects without the refinery having had to carry out a functional shutdown of the chimney or having resorted to risky human intervention on the superstructure .

Positive detections noted on the structure:

Cracks.

Bursts.

TECHNICAL INFORMATIONS

- Post-processing service : Drones Imaging company.

- Flights and aerial imagery : Fovéa Expertises company.

- Spatial accuracy : relative centimeter.

- Orthophoto RVB : GSD 0.6mm.

- Drone : Mikrokopter X6.

- Camera : Panasonic GH4.

- Photogrammetry software : Metashape.

- Export formats : GeoTiff and Obj.

- Delivery Delays : 3 days.